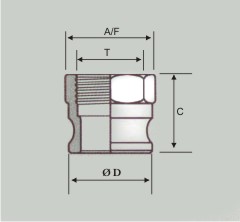

SR.No. |

SIZE |

A |

B |

C |

1 |

1/2″ |

119.4 |

54.7 |

54.1 |

2 |

3/4″ |

113.0 |

53.0 |

49.3 |

3 |

1″ |

133.1 |

63.2 |

63.5 |

4 |

1 1/4″ |

180.0 |

84.0 |

66.0 |

5 |

1 1/2″ |

190.6 |

82.1 |

72.6 |

6 |

2″ |

198.6 |

94.1 |

84.7 |

7 |

2 1/2″ |

210.0 |

109.2 |

83.9 |

8 |

3″ |

253.2 |

132.8 |

92.5 |

9 |

4″ |

272.2 |

160.4 |

93.2 |

10 |

5″ |

354.0 |

200.0 |

115.5 |

11 |

6″ |

422.0 |

258.0 |

112.0 |

| All the above couplings conform to DIN 2828 / MIL – C – 27487 | |

| Sizes | 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″, 4″, 5″, 6″ |

| Working Pressure | 5Kg/cm2 to 20 Kg/cm2 ( Working pressure varies according to the size of coupling) |

| Material | Aluminium, Bronze, Carbon Steel, S.S. 304, S.S. 316, PP |

| Application | Cement, Fertilizers, Fire Fighting Equipment, Ink / Dye / Paint Industries, Petrochemical / RefineriesProcess Industries, Mining, Oil Drilling Companies (Offshore / Onshore), Railways, Steel Plants, Military Applications, Pneumatic Conveyors, Oil Blending Plants, Automobile Manufacturers,Chemical Industries and Furnaces. |